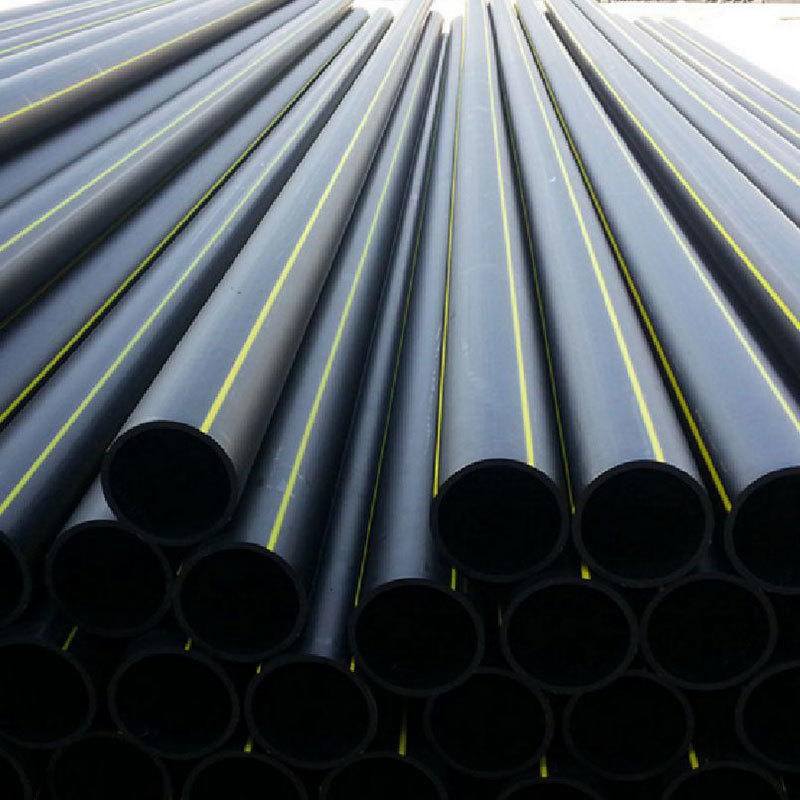

PE gas pipe

E-mail: lcsy365@126.com

Phone/WhatsApp: +86-13807214678

Product Description

Brief introduction of Liangcheng PE gas pipe

PE gas pipe adopts gas polyethylene pipe, which has many excellent performances and is applied in the field of gas transmission. The corrosion and joint leakage of steel pipes and cast iron pipes will be thoroughly solved, thus ensuring the safe operation of the gas pipeline network system. The PE gas pipe is made of inert material, which can resist the erosion of various chemical media. The pipe wall friction coefficient is low, the flow resistance is small, and the transmission capacity is strong. The electric melting connection is adopted. The interface strength is higher than the pipe body, and the fracture elongation of high toughness PE is generally more than 500%. PE gas pipe has good seismic performance, slow crack growth (SCG) resistance, rapid crack growth (RCP) resistance, flexibility and scratch resistance.

PE gas pipe has very strong adaptability to uneven settlement of pipe foundation and strong wear resistance. It can adopt a variety of trenchless methods, which greatly facilitates the construction and installation. The system cost is low and the maintenance cost is low, which can greatly reduce the project cost.

Executive standard of Liangcheng new material PE gas pipe

PE gas pipe shall comply with the national standard GB15558.1-2003.

PE gas pipe appearance: at least 3 yellow strips shall be extruded from the black pipe, and the color strips shall be evenly distributed along the circumference of the pipe.

Superior performance of Liangcheng PE gas pipeline

Reliable connection: polyethylene pipe systems are connected by electrothermal melting, and the strength of the joint is higher than the strength of the pipe body.

Good impact resistance at low temperature: the low-temperature embrittlement temperature of polyethylene is extremely low, and it can be safely used in the temperature range of - 60 ℃. During winter construction, due to the good impact resistance of the material, the pipe will not be brittle.

Good stress cracking resistance: HDPE has low notch sensitivity, high shear strength, excellent scratch resistance, and outstanding environmental stress cracking resistance.

Good chemical corrosion resistance: HDPE pipes can resist the corrosion of various chemical media, and the chemical substances in the soil will not cause any degradation to the pipes. Polyethylene is an insulator of electricity, so it will not decay, rust or electrochemical corrosion; In addition, it will not promote the growth of algae, bacteria or fungi.

Aging resistance and long service life: polyethylene pipes containing 2-2.5% uniformly distributed carbon black can be stored outdoors or used for 50 years without being damaged by ultraviolet radiation.

Good wear resistance: The wear resistance comparison test of HDPE pipe and steel pipe shows that the wear resistance of HDPE pipe is 4 times that of steel pipe. In the field of mud transportation, HDPE pipes have better wear resistance than steel pipes, which means that HDPE pipes have longer service life and better economy.

Good flexibility: The flexibility of HDPE pipe makes it easy to bend. In engineering, it can bypass obstacles by changing the direction of the pipe. In many cases, the flexibility of pipe can reduce the amount of pipe fittings and reduce the installation cost.

Low water flow resistance: HDPE pipes have smooth inner surface, and its Manning coefficient is 0.009. Smooth performance and non-adhesive properties ensure that HDPE pipes have higher conveying capacity than traditional pipes, and also reduce the pressure loss and water transmission energy consumption of the pipeline.

Convenient handling: HDPE pipe is lighter than concrete pipe, galvanized pipe and steel pipe. It is easy to handle and install. The lower labor and equipment requirements mean that the installation cost of the project is greatly reduced.

A variety of new construction methods: HDPE pipeline has a variety of construction technologies. In addition to the traditional excavation methods, it can also use a variety of new trenchless technologies such as pipe jacking, directional drilling, lining, pipe cracking, etc. This is the only choice for some places where excavation is not allowed, so HDPE pipeline is more widely used.

Application of PE gas pipe

Polyethylene (PE) gas pipeline has been widely used in the field of gas transmission and distribution successfully, and is favored by the majority of gas industry with its long service life, excellent corrosion resistance, reliable connection performance and safety performance, and low construction and maintenance costs. According to different grades of raw materials, polyethylene gas pipes are divided into two grades: PE80 and PE100; According to the standard size ratio, it is divided into two series, SDR11 and SDR17.6. SDR11 series is applicable to the transmission and distribution of natural gas, liquefied petroleum gas (gaseous), artificial gas and other gaseous media, and SDR17.6 series is applicable to the transmission and distribution of natural gas.

Specification of Liangcheng PE gas pipe

|

Nominal outer diameter dn mm |

SDR17.6 |

SDR11 |

||

|

Maximum working pressure≤0.602MPa |

Maximum working pressure≤1.0MPa |

|||

| Nominal wall thickness | Unit weight Kg/m | Nominal wall thickness | Unit weight Kg/m | |

|

20 |

2.3 |

0.135 |

3.0 |

0.169 |

|

25 |

2.3 |

0.173 |

3.0 |

0.219 |

|

32 |

2.3 |

0.224 |

3.0 |

0.279 |

|

40 |

2.3 |

0.284 |

3.7 |

0.432 |

|

50 |

2.9 |

0.440 |

4.6 |

0.669 |

|

63 |

3.6 |

0.689 |

5.8 |

1.06 |

|

75 |

4.3 |

0.980 |

6.8 |

1.48 |

|

90 |

5.2 |

1.42 |

8.2 |

2.14 |

|

110 |

6.3 |

2.09 |

10.0 |

3.18 |

|

125 |

7.1 |

2.74 |

11.4 |

4.12 |

|

140 |

8.0 |

3.44 |

12.7 |

5.13 |

|

160 |

9.1 |

4.39 |

14.6 |

6.74 |

|

180 |

10.3 |

5.70 |

16.4 |

8.52 |

|

200 |

11.4 |

6.85 |

18.2 |

10.50 |

|

225 |

12.8 |

8.64 |

20.5 |

13.30 |

|

250 |

14.2 |

10.67 |

22.7 |

16.35 |

|

280 |

15.9 |

14.1 |

25.4 |

20.50 |

|

315 |

17.9 |

16.89 |

28.6 |

25.95 |

|

355 |

20.2 |

22.10 |

32.3 |

33.03 |

|

400 |

22.8 |

28.00 |

36.4 |

41.92 |

|

450 |

25.6 |

34.50 |

40.9 |

52.95 |

|

500 |

28.4 |

42.53 |

45.5 |

66.08 |

|

560 |

31.9 |

53.44 |

50.9 |

82.00 |

|

630 |

35.8 |

67.48 |

57.3 |

103.9 |

1) Small-diameter pipes (with an outer diameter less than 50 mm) can be made into coils with a length of 50 m, 100 m or 150 m

2) The general length of large-diameter pipes is 6m, 9m or 12m, and the length can also be customized according to customer needs

Detail display

Keyword:

Categories:

Related Products

Get A Quote

Tell us more so we can connect you with the right person for your request.