Cold-formed metal corrugated culvert pipe

E-mail: lcsy365@126.com

Phone/WhatsApp: +86-13807214678

Product Description

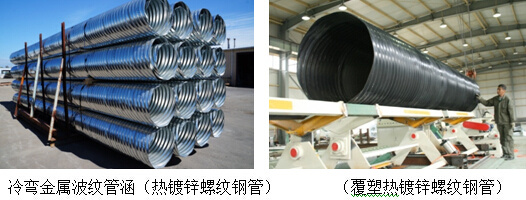

Brief introduction of cold-formed metal corrugated culvert pipe

Cold-formed metal corrugated culvert pipes include hot-dip galvanized spiral corrugated steel pipes and plastic-coated hot-dip galvanized spiral corrugated pipes, which are referred to as "threaded steel pipes" for short. The scope of application and engineering field are in accordance with CJ/T431-2013 Threaded Steel Pipes for Drainage. This standard is applicable to the plastic-coated threaded steel pipes used in non-pressure buried urban drainage, industrial drainage and other projects with the transmission medium temperature below 45 ℃, as well as the drainage and collection of urban rainwater Galvanized threaded steel pipe used in farmland water transmission and other projects.

The cold-formed metal corrugated culvert pipe is made of hot-dip galvanized steel strip as raw material on a special forming unit by crimping, spiral crimping and seaming. After the pipe is formed in spiral corrugated shape, it has high strength, stable structure, corrosion resistance, wear resistance, increased service life, and has the effects of economy, environmental protection, energy conservation and emission reduction, and convenient construction.

Pipe characteristics:

1. High strength

The cold-formed metal corrugated culvert pipe uses hot-dip galvanized steel strip as the base material, and the elastic modulus of steel is nearly 200 times that of HDPE. This excellent performance of steel is the theoretical basis of steel-plastic composite.

2. Long service life

The spiral corrugated steel pipe is made of hot-dip galvanized steel plate as the base material, after special treatment, and coated with polymer on both sides. The general durability is more than 80 years.

3. Convenient transportation and fast construction

The length of cold-formed metal corrugated culvert pipe can be determined as required (generally 6~12m). The weight is only 1/5 to 1/10 of that of the same diameter cement pipe. The pipe coupling is connected mechanically without electricity and heating. The pipe connection can be completed in a short time by manual operation.

4. Excellent economic characteristics

The standard length of cold-formed metal corrugated culvert pipe is 6m, which is easy to connect, time-saving and labor-saving. In addition to the advantages of light weight, convenient transportation and construction of original soil foundation, the cost of drainage pipe engineering is relatively low, and its construction cost is only about 50% of that of cement pipe. When construction is carried out in places where the use of machinery is limited, it can also be completed by manpower, which saves the cost of mechanical equipment such as forklifts and cranes, and is more economical than other drainage pipes.

Purpose

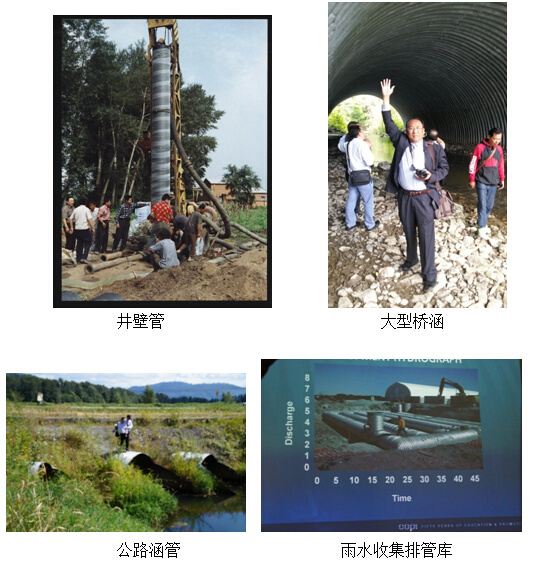

The cold-formed metal corrugated culvert pipe is mainly used for drainage and sewage discharge, urban drainage pipe network and sewage treatment plant, and can also be used for low pressure water transmission, farmland well drilling, electric power communication, and ground line protection and other projects.

Drainage: urban and rural sewage and rainwater pipes, drainage pipes for residential areas, golf courses, roads, railway drainage culverts, etc.

For protection: underground communication cables, gas and other external protection pipes can also be used for construction sites, protective sheds, etc.

Industrial use: factory drainage pipe, deep-water shaft wall pipe, coal mine gas ventilation pipe (negative pressure method).

Agricultural use: farmland well wall pipe, low pressure irrigation pipe.

Underground drainage pipe warehouse: build a "sponge city" to reduce runoff and store rainwater.

"Underground pipe gallery" of the branch line: super diameter (DN3000 - DN 40000) can also be used for the "underground pipe gallery" of the urban branch line or the "underground pipe gallery" of the industrial community and enterprises.

Construction

Please refer to the construction method of HDPE spiral wound structural wall pipe and the industrial standard "Screwed steel pipe for drainage" code CJ/T431-2013.

Pipe connection

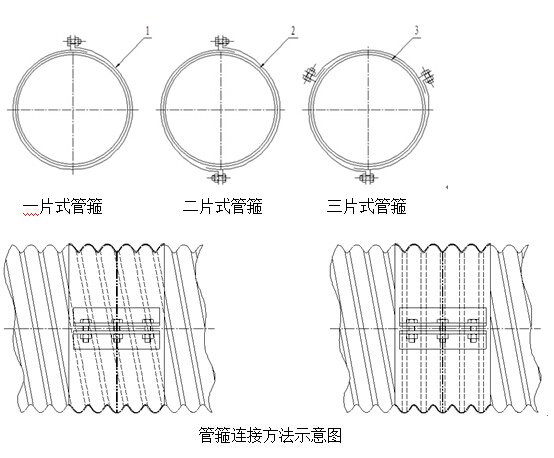

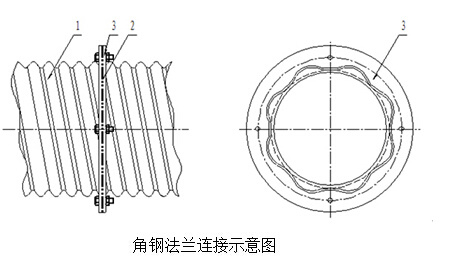

The mechanical coupling connection method and flange connection method are mainly used, which have the advantages of no heating, no electricity, and strong adaptability. The coupling connection method is to wrap the inner sealing gasket on the annular rib at both ends of the pipe, then wrap the steel coupling, and finally fasten it with movable shaft bolts. Angle steel flange connection can also be used.

Main technical indicators

Pipe specification: DN200 ~ 4000mm, pipe length: standard 6m/piece (maximum 12m), steel plate thickness: 1.0 ~ 3.2mm, zinc coating: 600g/㎡ on both sides, polymer coating thickness: 0.18 ~ 0.22mm, ring stiffness: SN4 ~ SN16.

Detail display

Keyword:

Categories:

Related Products

Get A Quote

Tell us more so we can connect you with the right person for your request.