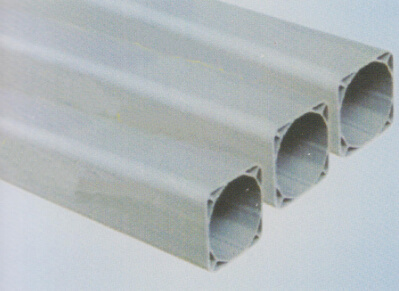

PVC grating pipe

E-mail: lcsy365@126.com

Phone/WhatsApp: +86-13807214678

Product Description

Introduction to PVC Grid Pipe:

The PVC grid pipe produced by Jingzhou Liangcheng is a perforated rectangular (with a certain radian at the corner) plastic pipe composed of several square structures. The product has multiple hole positions, which can be directly threaded, and the pipe hole can be reserved at the same time to improve the utilization rate of communication hole positions. The connection of PVC grid pipes produced by Jingzhou Liangcheng Technology Co., Ltd. adopts a socket structure. The connection between pipes can be completed without any tools, which is convenient for construction and maintenance. The pipes and pipe joint sleeves are bonded with special PVC glue, which has better connection sealing and is not easy to seep.

Characteristics of Liangcheng PVC Grid Tube

Strong compression resistance

The high-quality anti-aging modified PVC engineering plastic is used for one-time extrusion, with high compressive strength and honeycomb reasonable mechanical structure, which makes the compression performance of the pipe 10-100 times higher than that of the ordinary plastic pipe. Under normal conditions, no foundation or encapsulation is required to prevent settlement. It can replace the steel pipe to safely cross the road, prevent fire (good flameout), resist corrosion and aging, and have a service life of more than 50 years.

Complete specifications

The product portfolio is diverse, the appearance is beautiful, and the main specifications include single hole, 3 holes, 4 small and medium holes, and 5 holes with the same diameter and different diameter. The size of 6 holes, 7 holes, 8 holes, and 9 holes are matched with optical (electric) cables of different diameters. They can be freely transited and combined with the original cement pipes and corrugated pipes, and have corresponding joints, plugs, ties, special glue and other accessories, which are convenient for construction operation.

Structural innovation

The pipe position is saved, the pipe structure is tight, and the pavement excavation is small, only 10% of the cement pipe position, which effectively saves the urban underground pipe position resources, and has little impact on the road traffic and municipal administration.

Good toughness

Bend a free length of 6m pipe with a bending radius of up to 4m. It can be easily opened when encountering obstacles or crossing other pipelines during construction.

Convenient construction

It saves labor and time, and the sheath is integrated with the sub-pipe. The cable can be laid in one time without three times of sub-pipe laying, which avoids the deformation and kink of the secondary sub-pipe laying, the confusion of the sequence, the trouble of repeated construction, light weight, and convenient handling; The inner wall is smooth, the threading force is small, and the compression resistance is strong. The buried depth is only 0.3-0.5 meters. There is no need to do foundation and cement encapsulation. The traffic can be opened after backfilling 20 cm of fine sand and then backfilling. There is no need to do foundation and cement encapsulation when crossing the road. When PE is used, the cement pouring needs a maintenance period, and the optical cable can only be put through the sub-pipe at one time. It is perishable. The construction period of using grid honeycomb is nearly 1/2 shorter than that of using PE pipe, and nearly 3/5 shorter than that of using cement and steel pipe.

High utilization

The comprehensive cost is low, the sheath and sub-tube are integrated, and the effective space of the inner hole can be connected and used after being cut off, which saves material consumption and reduces project investment. Compared with the use of PE pipe, it can save 20% of the cost and can replace the steel pipe, saving about 50% of the investment

Detail display

Keyword:

Categories:

Related Products

Get A Quote

Tell us more so we can connect you with the right person for your request.