Understanding Porous Silicon Core Cluster Tubes: Applications and Benefits in Industrial Piping

Dec 22,2024

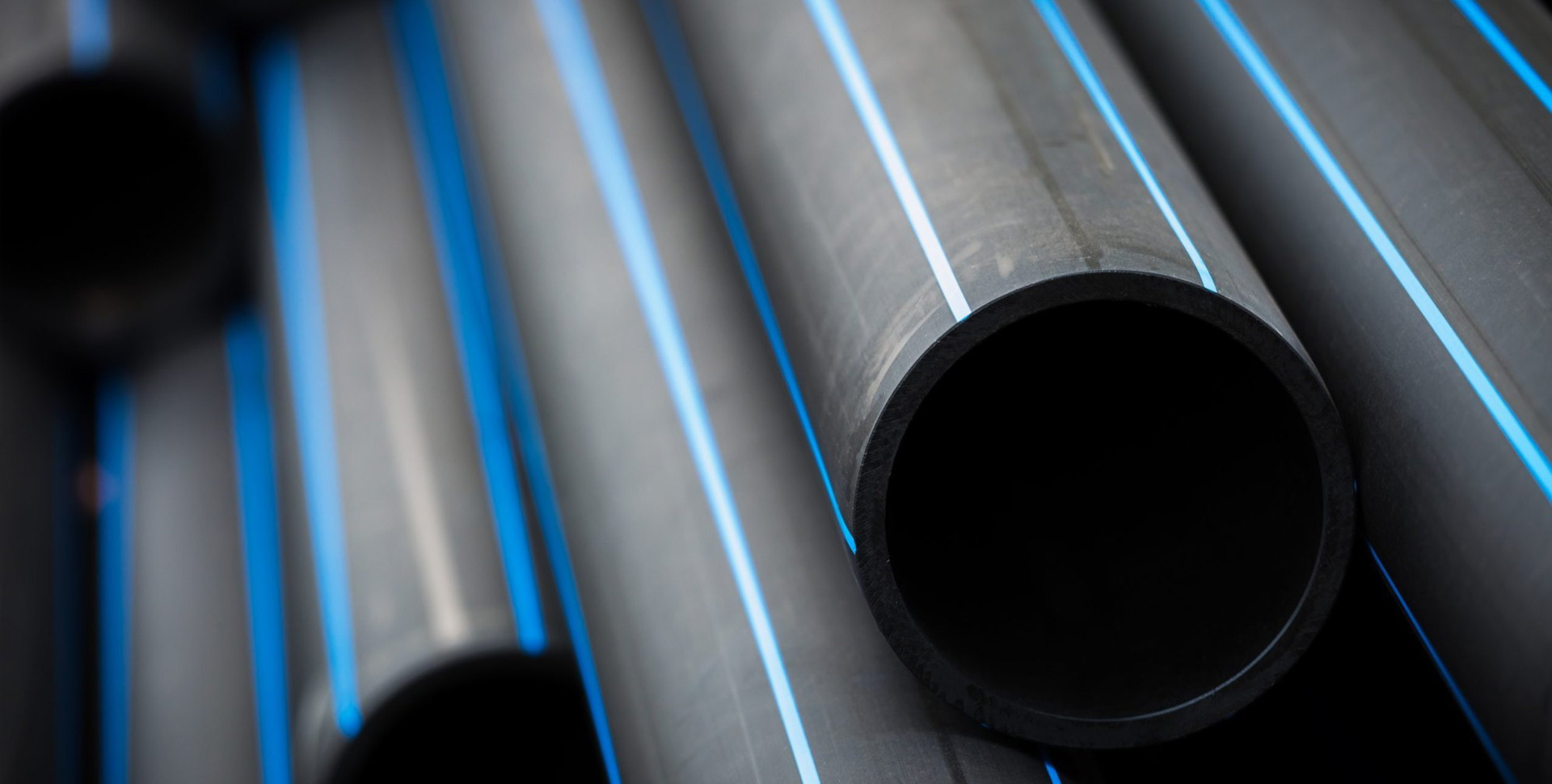

Porous silicon core cluster tubes represent a significant advancement in industrial piping technology. These specialized tubes are engineered from porous silicon, a material known for its unique structural properties and versatility. The incorporation of porous silicon offers several benefits that can enhance the overall performance of piping systems in various industrial applications.

One of the primary advantages of using porous silicon core cluster tubes is their lightweight nature. Compared to traditional materials, these tubes reduce overall system weight, which can lead to easier handling and installation. This characteristic is particularly important in industries where weight reduction can translate into lower operational costs and improved efficiency.

Another essential feature of porous silicon core cluster tubes is their enhanced permeability. The porous structure allows for better fluid flow and gas exchange, making them suitable for applications where efficient transport of materials is crucial. This property is particularly beneficial in chemical processing, water treatment, and gas distribution systems, where consistent flow rates and minimal resistance are required.

In addition to their functional benefits, porous silicon core cluster tubes also provide excellent thermal stability. They can withstand high temperatures and harsh environments, making them ideal for a variety of industrial settings. This thermal resilience ensures that the tubes maintain their structural integrity over time, reducing the need for frequent replacements or repairs.

Moreover, the porous nature of these tubes contributes to their ability to trap and filter particulate matter. This property is essential in applications that require the purification of gases or liquids, as it helps in minimizing contamination and enhancing product quality. Industries such as pharmaceuticals, food and beverage, and environmental monitoring can greatly benefit from this filtering capability.

The versatility of porous silicon core cluster tubes extends to their adaptability in various configurations. They can be tailored to meet specific requirements, including different lengths, diameters, and porosity levels. This customization allows engineers and designers to create solutions that fit unique operational needs, enhancing overall system performance.

In conclusion, porous silicon core cluster tubes are a remarkable addition to the industrial piping landscape. Their lightweight nature, enhanced permeability, thermal stability, and filtering capabilities make them a valuable choice for a range of applications. As industries continue to seek innovative solutions to improve efficiency and reduce costs, the adoption of porous silicon core cluster tubes is likely to grow, paving the way for advancements in industrial processes and technologies.

One of the primary advantages of using porous silicon core cluster tubes is their lightweight nature. Compared to traditional materials, these tubes reduce overall system weight, which can lead to easier handling and installation. This characteristic is particularly important in industries where weight reduction can translate into lower operational costs and improved efficiency.

Another essential feature of porous silicon core cluster tubes is their enhanced permeability. The porous structure allows for better fluid flow and gas exchange, making them suitable for applications where efficient transport of materials is crucial. This property is particularly beneficial in chemical processing, water treatment, and gas distribution systems, where consistent flow rates and minimal resistance are required.

In addition to their functional benefits, porous silicon core cluster tubes also provide excellent thermal stability. They can withstand high temperatures and harsh environments, making them ideal for a variety of industrial settings. This thermal resilience ensures that the tubes maintain their structural integrity over time, reducing the need for frequent replacements or repairs.

Moreover, the porous nature of these tubes contributes to their ability to trap and filter particulate matter. This property is essential in applications that require the purification of gases or liquids, as it helps in minimizing contamination and enhancing product quality. Industries such as pharmaceuticals, food and beverage, and environmental monitoring can greatly benefit from this filtering capability.

The versatility of porous silicon core cluster tubes extends to their adaptability in various configurations. They can be tailored to meet specific requirements, including different lengths, diameters, and porosity levels. This customization allows engineers and designers to create solutions that fit unique operational needs, enhancing overall system performance.

In conclusion, porous silicon core cluster tubes are a remarkable addition to the industrial piping landscape. Their lightweight nature, enhanced permeability, thermal stability, and filtering capabilities make them a valuable choice for a range of applications. As industries continue to seek innovative solutions to improve efficiency and reduce costs, the adoption of porous silicon core cluster tubes is likely to grow, paving the way for advancements in industrial processes and technologies.

Latest News