Understanding Highway Silicon Core Tubes: Essential Insights for Electrical Professionals

Dec 18,2024

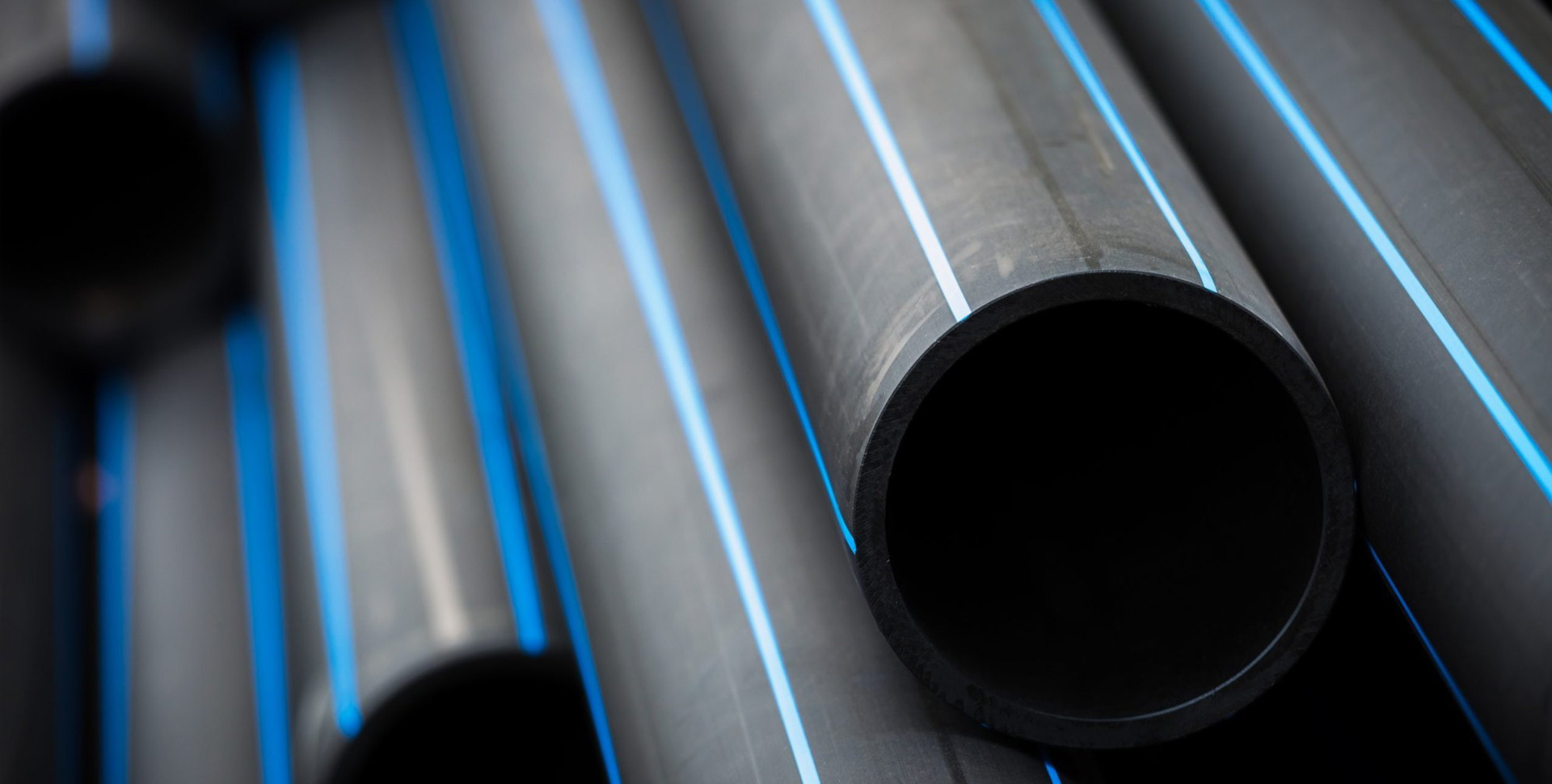

Highway silicon core tubes represent a significant advancement in the electrical and cable industry. These tubes are primarily used as protective conduits for electrical wires and cables, particularly in environments where durability and resistance to external factors are paramount. As professionals in the electrical sector, understanding the applications and benefits of silicon core tubes can enhance operational efficiency and safety.

One of the primary advantages of highway silicon core tubes is their exceptional resistance to extreme temperatures. Unlike traditional materials, silicons can withstand a wide range of temperatures, making them ideal for use in various environments, including those that experience rapid temperature fluctuations. This characteristic ensures that the electrical systems remain functional without risk of damage, thus protecting essential infrastructure.

Another significant benefit is the flexibility and lightweight nature of silicon core tubes. These properties facilitate easier installation and handling compared to more rigid materials. Professionals can save valuable time and labor costs during installation, especially in complex projects where traditional conduits may pose challenges. The lightweight design also minimizes the structural load on overhead installations, making them a preferred choice for numerous applications.

Highway silicon core tubes also provide excellent electrical insulation properties. This feature reduces the risk of electric shock and improves safety for both workers and end-users. When used in conjunction with high-quality cables, these tubes can effectively mitigate electrical interference, ensuring the integrity of signal transmission in various applications, from telecommunications to power distribution.

In addition to their protective and insulating properties, highway silicon core tubes are designed to be resistant to chemical degradation. This durability makes them suitable for use in industrial settings where exposure to chemicals, oils, or other hazardous materials is a concern. By incorporating silicon core tubes in cable management systems, professionals can ensure longer-lasting installations that require less frequent maintenance and replacement.

When considering the deployment of highway silicon core tubes, it is essential to follow industry best practices. This includes proper installation techniques, adherence to safety standards, and regular maintenance checks to ensure optimal performance. Professionals should also stay informed about the latest advancements in cable technology and materials to make well-informed decisions for their projects.

In conclusion, highway silicon core tubes offer numerous advantages that can enhance the safety, efficiency, and longevity of electrical installations. By understanding their properties and applications, professionals can leverage this technology to improve their operational practices and deliver reliable solutions in the electrical industry. Embracing these innovations will not only benefit individual projects but also contribute to the overall progress of the electrical sector.

One of the primary advantages of highway silicon core tubes is their exceptional resistance to extreme temperatures. Unlike traditional materials, silicons can withstand a wide range of temperatures, making them ideal for use in various environments, including those that experience rapid temperature fluctuations. This characteristic ensures that the electrical systems remain functional without risk of damage, thus protecting essential infrastructure.

Another significant benefit is the flexibility and lightweight nature of silicon core tubes. These properties facilitate easier installation and handling compared to more rigid materials. Professionals can save valuable time and labor costs during installation, especially in complex projects where traditional conduits may pose challenges. The lightweight design also minimizes the structural load on overhead installations, making them a preferred choice for numerous applications.

Highway silicon core tubes also provide excellent electrical insulation properties. This feature reduces the risk of electric shock and improves safety for both workers and end-users. When used in conjunction with high-quality cables, these tubes can effectively mitigate electrical interference, ensuring the integrity of signal transmission in various applications, from telecommunications to power distribution.

In addition to their protective and insulating properties, highway silicon core tubes are designed to be resistant to chemical degradation. This durability makes them suitable for use in industrial settings where exposure to chemicals, oils, or other hazardous materials is a concern. By incorporating silicon core tubes in cable management systems, professionals can ensure longer-lasting installations that require less frequent maintenance and replacement.

When considering the deployment of highway silicon core tubes, it is essential to follow industry best practices. This includes proper installation techniques, adherence to safety standards, and regular maintenance checks to ensure optimal performance. Professionals should also stay informed about the latest advancements in cable technology and materials to make well-informed decisions for their projects.

In conclusion, highway silicon core tubes offer numerous advantages that can enhance the safety, efficiency, and longevity of electrical installations. By understanding their properties and applications, professionals can leverage this technology to improve their operational practices and deliver reliable solutions in the electrical industry. Embracing these innovations will not only benefit individual projects but also contribute to the overall progress of the electrical sector.

Latest News