Understanding Traffic Engineering Cluster Tubes in Automotive Applications

Mar 06,2025

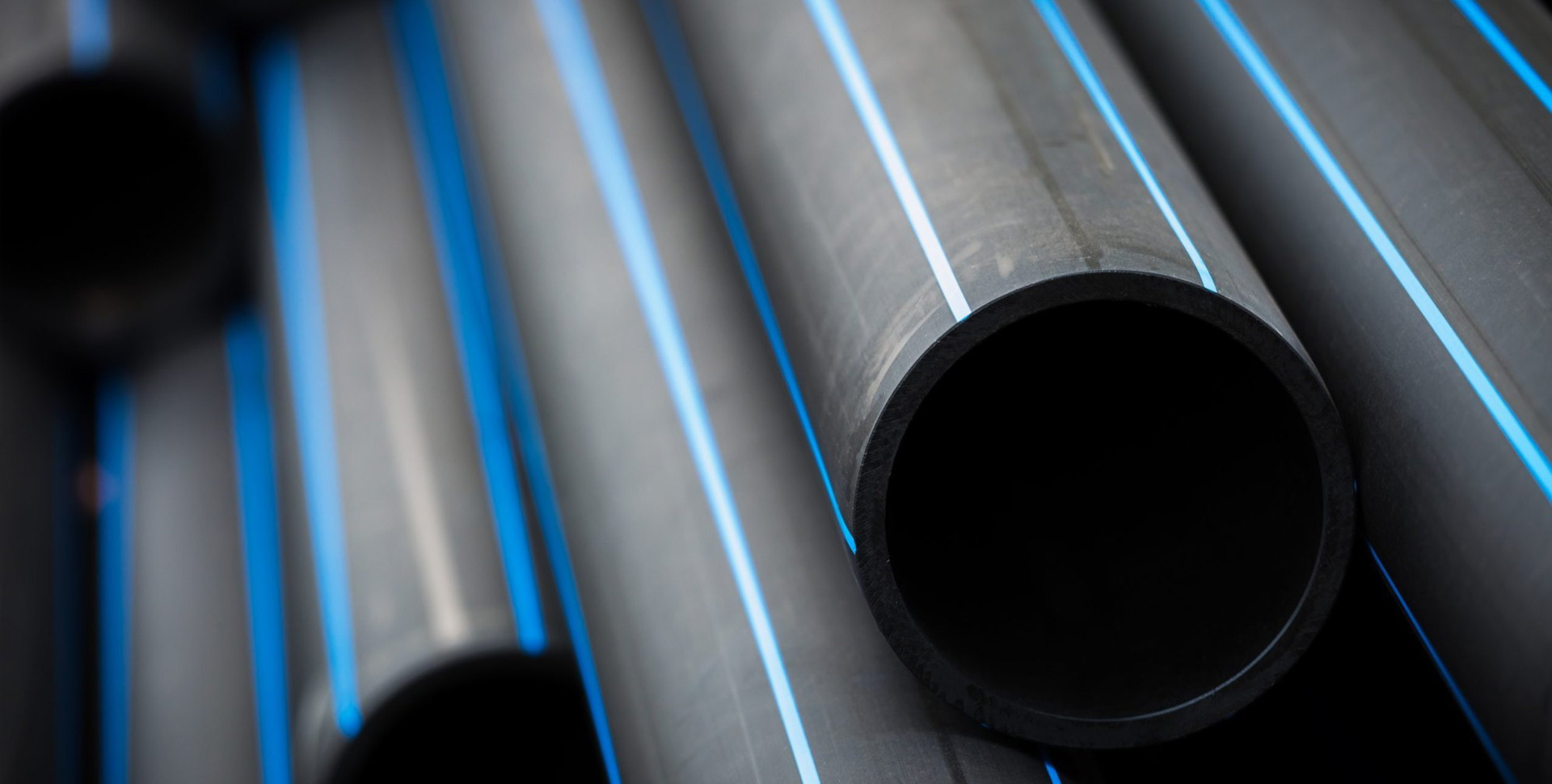

Traffic engineering cluster tubes play a critical role in the design and functionality of rubber hoses within the automotive industry. These tubes are designed to manage the flow of various fluids, including coolant, fuel, and air, ensuring that automotive systems operate efficiently and safely. The engineering behind these cluster tubes allows for optimized flow characteristics which are essential for maintaining the performance of vehicles.

The structure of traffic engineering cluster tubes is typically reinforced to withstand high pressures and temperature variations. This is particularly important in automotive applications where hoses must endure fluctuating environmental conditions and the mechanical stresses associated with vehicle operation. The integration of advanced materials in the manufacturing of these tubes enhances their durability and resistance to degradation, which is crucial for longevity and reliability.

In the field of automotive engineering, understanding the dynamics of traffic engineering cluster tubes can help in the development of more efficient systems that support performance and fuel economy. Engineers focus on several key aspects, such as the geometry of the tubes, the types of materials used, and the methods of joining different segments. A well-designed cluster tube not only simplifies the routing of hoses but also minimizes pressure drops and optimizes fluid dynamics, contributing to overall vehicle efficiency.

Moreover, traffic engineering cluster tubes are pivotal in the context of vehicle safety. High-quality rubber hoses that incorporate these tubes are less prone to leaks and failures, which can lead to hazardous situations. The automotive industry continuously seeks to improve designs through research and development, aiming for innovations that enhance performance while ensuring compliance with safety regulations.

As the automotive industry shifts towards more sustainable practices, the role of traffic engineering cluster tubes will likely evolve. The push for electric vehicles and alternative fuel systems places additional demands on hose systems, necessitating the development of cluster tubes that can handle new fluid types and pressures. This evolution highlights the importance of adaptability and innovation in materials and engineering practices.

In conclusion, traffic engineering cluster tubes are fundamental components in automotive rubber hose applications. Their design and functionality are crucial for efficient fluid management, vehicle performance, and safety. As the industry progresses, ongoing advancements in materials and engineering techniques will continue to enhance the reliability and efficiency of these critical components, supporting the future of automotive engineering. Understanding these elements will empower professionals in the industry to make informed decisions regarding product development and system optimization.

The structure of traffic engineering cluster tubes is typically reinforced to withstand high pressures and temperature variations. This is particularly important in automotive applications where hoses must endure fluctuating environmental conditions and the mechanical stresses associated with vehicle operation. The integration of advanced materials in the manufacturing of these tubes enhances their durability and resistance to degradation, which is crucial for longevity and reliability.

In the field of automotive engineering, understanding the dynamics of traffic engineering cluster tubes can help in the development of more efficient systems that support performance and fuel economy. Engineers focus on several key aspects, such as the geometry of the tubes, the types of materials used, and the methods of joining different segments. A well-designed cluster tube not only simplifies the routing of hoses but also minimizes pressure drops and optimizes fluid dynamics, contributing to overall vehicle efficiency.

Moreover, traffic engineering cluster tubes are pivotal in the context of vehicle safety. High-quality rubber hoses that incorporate these tubes are less prone to leaks and failures, which can lead to hazardous situations. The automotive industry continuously seeks to improve designs through research and development, aiming for innovations that enhance performance while ensuring compliance with safety regulations.

As the automotive industry shifts towards more sustainable practices, the role of traffic engineering cluster tubes will likely evolve. The push for electric vehicles and alternative fuel systems places additional demands on hose systems, necessitating the development of cluster tubes that can handle new fluid types and pressures. This evolution highlights the importance of adaptability and innovation in materials and engineering practices.

In conclusion, traffic engineering cluster tubes are fundamental components in automotive rubber hose applications. Their design and functionality are crucial for efficient fluid management, vehicle performance, and safety. As the industry progresses, ongoing advancements in materials and engineering techniques will continue to enhance the reliability and efficiency of these critical components, supporting the future of automotive engineering. Understanding these elements will empower professionals in the industry to make informed decisions regarding product development and system optimization.

Latest News