Elevate Your Machinery with Porous Communication Power Tubes: Revolutionizing Plastic Processing

Oct 14,2024

Elevate Your Machinery with Porous Communication Power Tubes

Introduction to Porous Communication Power Tubes

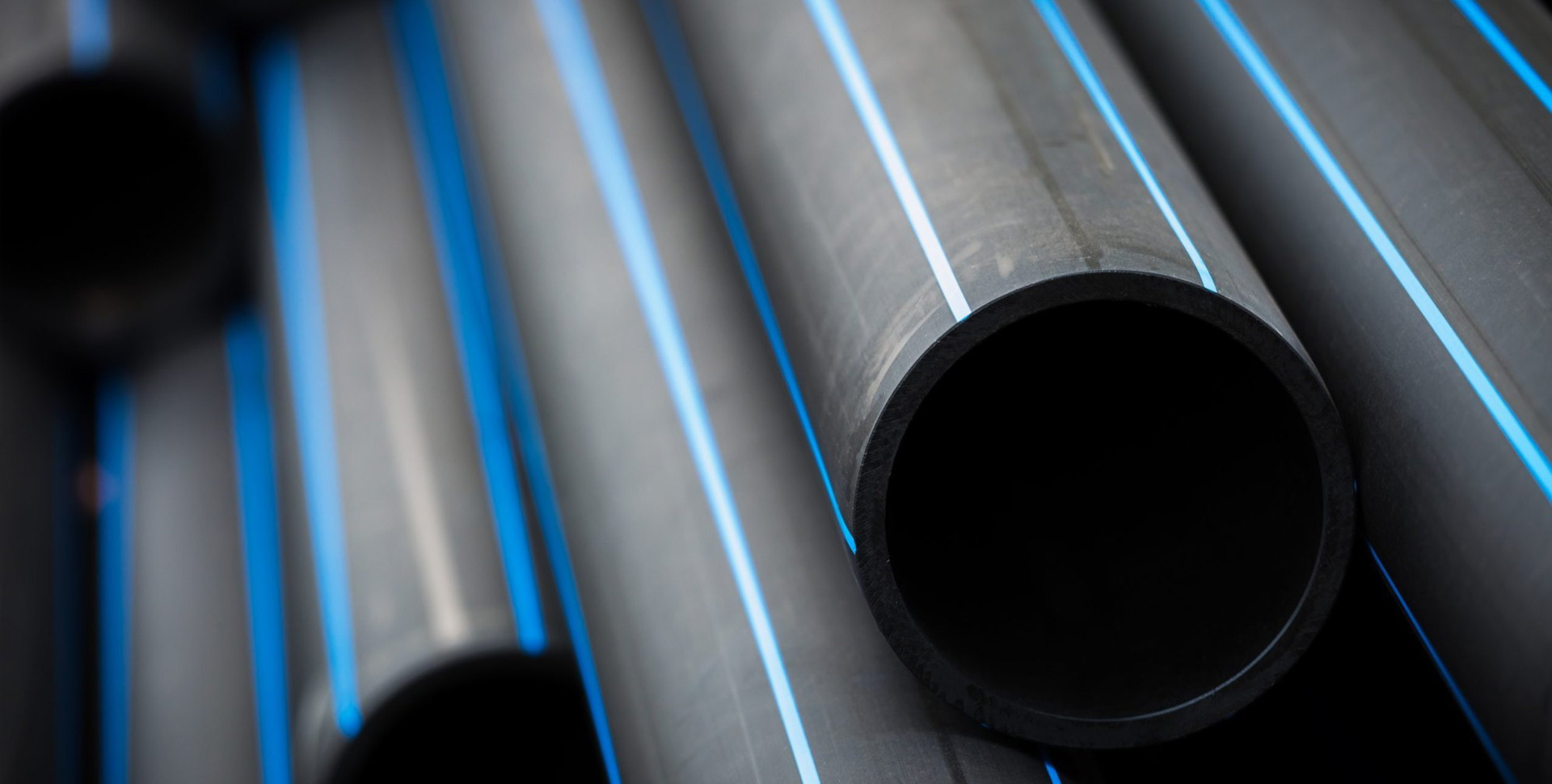

In the ever-evolving landscape of **manufacturing and processing machinery**, the quest for efficiency and innovation remains paramount. **Porous communication power tubes** have emerged as a groundbreaking solution in the field of **plastic processing machinery**. These advanced components not only streamline operations but also enhance the performance and accuracy of machinery involved in plastic pipe production and other applications.

This article delves into the myriad benefits of porous communication power tubes, their applications, and their role in transforming the industry.

Understanding Porous Communication Power Tubes

What Are Porous Communication Power Tubes?

Porous communication power tubes are specialized conduits designed to facilitate the seamless transmission of power and data between various components of manufacturing machinery. These tubes are characterized by their porous structure, which allows for efficient airflow, cooling, and heat dissipation while maintaining a compact design.

Key Features of Porous Communication Power Tubes

1. **Enhanced Thermal Management**: The porous structure allows for superior heat dissipation, preventing overheating of machinery components.

2. **Flexible Design**: These tubes can be tailored to fit various machinery configurations, making them suitable for diverse applications.

3. **Durability**: Made from high-quality materials, porous communication power tubes are designed to withstand the rigors of a manufacturing environment.

4. **Efficient Data Transmission**: The design allows for effective communication between different machinery parts, enabling real-time monitoring and control.

The Benefits of Using Porous Communication Power Tubes in Machinery

Increased Efficiency and Performance

Utilizing porous communication power tubes can significantly improve the overall efficiency of plastic processing machinery. With enhanced thermal management and effective data transmission, manufacturers can expect a reduction in downtime and increased output.

Cost-Effectiveness

Investing in porous communication power tubes can lead to long-term savings. By optimizing machinery performance and reducing the likelihood of failures, manufacturers can minimize maintenance costs and increase productivity.

Environmental Sustainability

As industries strive for sustainable practices, porous communication power tubes contribute to energy efficiency. Their design minimizes energy loss, making them an eco-friendly choice for modern manufacturing processes.

Applications of Porous Communication Power Tubes

Plastic Pipe Production

In the realm of **plastic pipe manufacturing**, porous communication power tubes play a critical role. They enhance the efficiency of extrusion processes by maintaining optimal temperatures and facilitating smooth operations.

Injection Molding Machines

Injection molding processes benefit from the use of porous communication power tubes by improving cooling efficiency. This leads to faster cycle times and higher-quality finished products.

Blow Molding Applications

In blow molding, these tubes contribute to consistent pressure control and cooling, ensuring the production of high-quality plastic products with reduced defects.

Innovations in Porous Communication Power Tube Technology

Advanced Materials

Recent advancements in materials science have led to the development of more resilient and lightweight porous communication power tubes. These materials enhance performance while reducing the overall weight of the machinery.

Integration with IoT

The integration of porous communication power tubes with Internet of Things (IoT) technologies allows for real-time monitoring and predictive maintenance. This capability ensures that machinery operates at peak performance while minimizing unexpected downtime.

Choosing the Right Porous Communication Power Tube for Your Machinery

Assessing Your Machinery Needs

Before selecting a porous communication power tube, it is essential to evaluate your specific machinery requirements. Consider the size, weight, and operational environment to ensure compatibility.

Consulting with Experts

Working with industry experts can provide valuable insights into the best porous communication power tube solutions for your specific applications. This collaboration can lead to optimized performance and cost savings.

FAQs About Porous Communication Power Tubes

1. What materials are porous communication power tubes made from?

Porous communication power tubes are typically made from high-performance polymers or composites designed to withstand high temperatures and corrosive environments.

2. How do porous communication power tubes improve thermal management?

Their porous structure allows for better airflow and heat dissipation, preventing overheating and ensuring stable operation of machinery.

3. Can porous communication power tubes be customized?

Yes, these tubes can be tailored to fit specific machinery configurations and operational requirements.

4. What industries benefit from using porous communication power tubes?

Industries such as plastic processing, automotive, and electronics manufacturing can significantly benefit from the use of these innovative tubes.

5. Are porous communication power tubes cost-effective?

Yes, while the initial investment may be higher, the long-term savings in maintenance and increased productivity make them a cost-effective choice.

Conclusion

In summary, **porous communication power tubes** represent a significant advancement in the manufacturing of plastic processing machinery. Their unique properties contribute to enhanced efficiency, reduced costs, and improved sustainability. As industries continue to innovate and adapt to changing market demands, the integration of these advanced components will undoubtedly play a pivotal role in shaping the future of manufacturing. By embracing the benefits of porous communication power tubes, manufacturers can elevate their operations and remain competitive in an increasingly challenging landscape.

Latest News