What is the strength of PE water supply pipe to take the lead in the field of water supply pipe?

Sep 04,2020

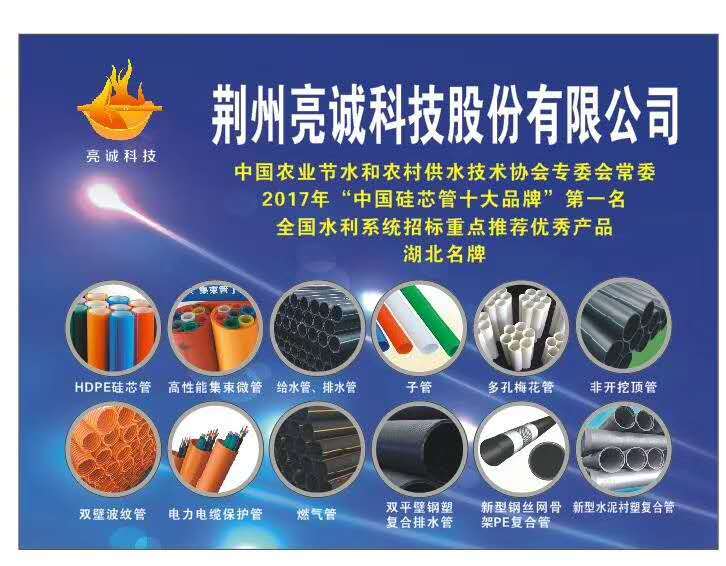

PE (polyethylene) material is widely used in the field of water supply pipe manufacturing due to its high strength, corrosion resistance, non-toxic and other characteristics. Because it will not rust, it is an ideal pipe material to replace ordinary water supply pipes.

The same is "plastic pipe". What's the difference between PE water supply pipe and other water supply pipes? Why can PE water supply pipe take the lead?

PE water supply pipe has ten characteristics, which lay the foundation for it to take the lead in the field of water supply pipe.

1. Long service life: under normal conditions, HDPE material is not vulnerable to ultraviolet radiation, and its service life can reach 50 years.

2. Good hygiene: PE pipes are non-toxic, free of heavy metal additives, free from scaling and bacteria, which greatly solves the problem of secondary pollution of drinking water. Comply with national safety evaluation standards and relevant health and safety regulations of the Ministry of Health.

3. It can resist the corrosion of various chemical media: HDPE pipes can resist the corrosion of various chemical media, and the compounds in the soil layer are not easy to dissolve the pipes.

4. The inner wall is smooth, the friction coefficient is extremely low, and the passing capacity of the medium is correspondingly improved and has excellent wear resistance, which is 4 times of that of the steel pipe.

5. Good stress cracking resistance: HDPE has low vacancy sensitivity, high shear strength and excellent scratch resistance, and environmental stress cracking resistance is also very prominent.

6. Light weight, convenient transportation and installation: HDPE pipe is lighter than other pipes, it is very easy to transport and install, lower requirements for human resources and machinery and equipment, greatly reducing the installation cost of the project.

7. The unique electrofusion connection, hot-melt butt joint and hot-melt socket connection technology make the interface strength high with the pipe body, ensuring the safety and reliability of the interface.

8. Good low-temperature impact resistance: PE pipe has a low-temperature embrittlement point of - 70 ℃, which is superior to other pipes. During winter construction, due to the good impact resistance of raw materials, it is not easy to produce pipe brittle cracks.

9. The color of PE environmental protection and health water supply pipe is blue or black with blue line, other colors need to be customized, and the color of accessories corresponds to the color of the pipe.

10. Low water flow resistance: HDPE pipes have smooth inner surface, and its Manning coefficient is 0.009. Smooth performance and non-adhesive properties ensure that HDPE pipes have higher conveying capacity than traditional pipes, and also reduce the pressure loss and water transmission energy consumption of the pipeline.

Latest News